86 17344894490

service@chalcoaluminum.com

- Aluminum Forgings for Rail Vehicles

- Aluminum plate sheet for rail Rail vehicles

- Aluminum Profile for Rail Vehicles

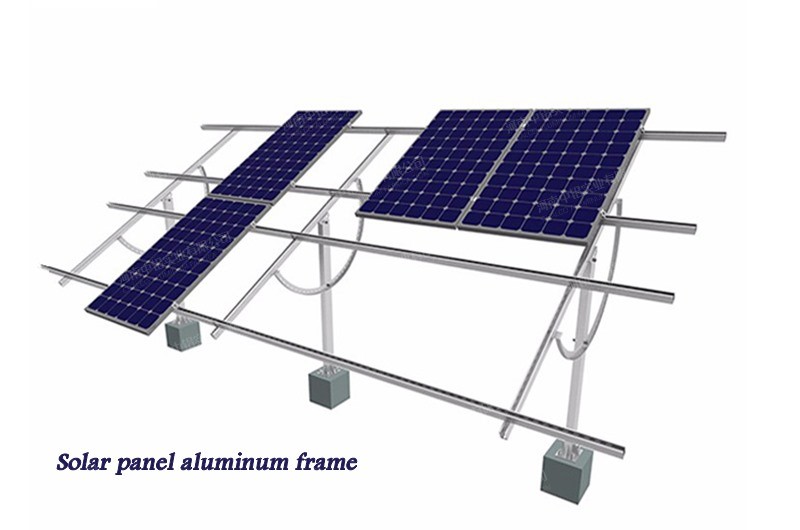

Solar panel aluminum frame

Since the 1970s, solar energy technology has been promoted by scientists and engineers all over the world. The use of solar energy is changing with each passing day. At present, with the increasingly developed technology, solar energy

Solar panel aluminum frame

Photovoltaic panels are more and more widely used. In advocating environmental protection and building a green ecological society

In the 21st century, solar energy, as a clean new energy, has become one of the seven new energy sources that China has determined to focus on

One of the most popular industries. Solar panel aluminum frame is favored because of the following advantages:

- (1) The weight is relatively light, but the strength is high;

- 2) Superior anti-corrosion performance and long service life;

- 3) Easy installation and good flexibility;

- 4) In areas with large temperature difference, aluminum profiles are less affected than steel, and low temperature is not harmful

- Brittle cracking.

In order to improve the production efficiency of solar panel aluminum frame, changes can be made in the following aspects:

(1) Properly adjust the alloy composition, appropriately increase the Si content in the range and enhance the extrusion. And the aluminum rod for producing solar aluminum frame must be homogenized;

2) When designing the die, B faces the lower notch and discharges the material upward, which is shortened within an appropriate range

For the die working belt, the upper die shall be thinned appropriately, the bridge position shall be changed to water drop bridge position, which is suitable for the chamfering of the feed inlet

When the pressure is increased, the feed pressure is reduced, which is conducive to improve the extrusion speed of the product;

3) During mold maintenance, the maintenance is carried out according to the template, mainly through various hands

Adjust the metal flow rate in the extrusion section, and conduct rod limiting production according to the nitriding condition of the die;

4) During extrusion production, the rod drying measures shall be taken to control the aluminum rod temperature at 430-450 ℃,

Provide temperature rise space for extrusion speed increase, and the discharge speed is increased from the original 16m / min to the current 21m / min.

Free offer of products, welcome to consult at any time, we will give the first reply.Our Email: