86 17344894490

service@chalcoaluminum.com

- Aluminum Forgings for Rail Vehicles

- Aluminum plate sheet for rail Rail vehicles

- Aluminum Profile for Rail Vehicles

Foamed aluminum for railway passenger cars

How to reduce the dead weight of railway passenger cars, so as to save traction kinetic energy, reduce train operation cost, reduce passenger compartment noise and improve passenger comfort has always been an important direction of railway passenger car technology development at home and abroad, and the goal of vehicle design. The light weight of passenger cars and the noise control of passenger compartments are often realized by using new materials.

Compared with metal aluminum with specific gravity of 2.7, by using titanium hydride as foaming agent, the volume of foam aluminum can be expanded to 13 times of the original, and the specific gravity can be reduced to 0.2 ~ 0.4, which is equivalent to 1 / 3 of wood. In addition to its ultra light characteristics, it also has excellent mechanical, acoustic, thermal and other properties. It has broad application prospects in the fields of architecture, automobile, railway passenger car, military and so on, especially in today's world

At the time of advocating energy conservation and emission reduction, it has more important diachronic significance.

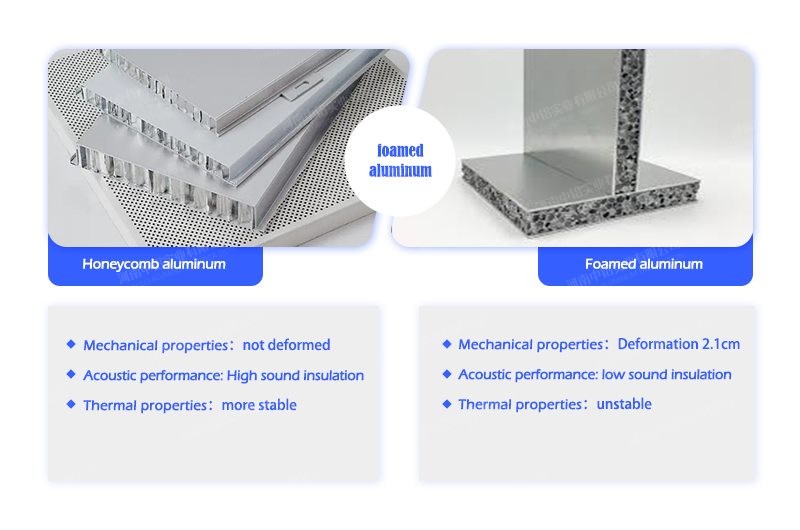

Taking foamed aluminum sandwich panel and aluminum honeycomb sandwich panel with a total thickness of 14.5mm (sandwich layer of 12mm) as an example, the properties of foamed aluminum and aluminum honeycomb were compared and analyzed.

Mechanical properties. In general, the strength of foamed aluminum is about 1% of that of dense aluminum, and the elastic modulus is about 1 / 50 ~ 1 / 100 of that of dense aluminum. The excellent mechanical properties of foamed aluminum are reflected in its compression and fatigue properties. When compressed, foamed aluminum shows a wide stress section at a certain stress level. For example, in

Under the same pressure load of 1000 kg, the comparative test results of 14.5 mm foamed aluminum sandwich plate and aluminum honeycomb sandwich plate show that the deformation of aluminum honeycomb is about 2.1mm, while there is basically no deformation of foamed aluminum.

Acoustic performance. The excellent acoustic performance of foamed aluminum is reflected in the damping, sound insulation and sound absorption performance. As a macro material, foamed aluminum is composed of aluminum metal frame and pores (which can be regarded as the second phase gas). There are a large number of micro and macro defects inside. A large number of interfaces formed between pores and matrix increase the gap between the two phases

Defects interact to produce extremely uneven microstructure and stress state. When the external force acts on the organization, it intensifies the uneven stress state, causes dislocation movement and plastic slip in the defect area, increases the dislocation density, and produces a large strain phase difference between the frame and the hole, so as to form a two-phase interface

Internal friction is generated at the, which converts mechanical properties into heat energy. The sound insulation performance of foamed aluminum core material is higher than that of aluminum honeycomb core plate with the same thickness. Compared with other sound insulation materials, foamed aluminum not only has wide sound absorption band, but also has good low-frequency sound absorption performance.

Thermal properties. The melting point of foamed aluminum is basically the same as that of aluminum, but affected by the oxide layer on the surface of foam, the melting point temperature of foamed aluminum is higher than the theoretical melting point. When the oxide layer is thick enough and the temperature is higher than the melting point of aluminum without external force, the thick oxide layer can support the porous structure of foamed aluminum. If heating is continued in an oxidizing environment, the thickness of the oxide layer will increase and the foamed aluminum will become more stable. foaming

There is air medium with low thermal conductivity system in the pores of aluminum material. The thermal conductivity of foamed aluminum is much lower than that of aluminum metal, which is about 1 / 60 of that of aluminum, and the thermal conductivity decreases exponentially with the increase of pore clearance rate. Under the same conditions, the combustion comparison test of aluminum honeycomb plate and foamed aluminum core material was carried out. The surface of aluminum honeycomb sandwich plate began to melt at 20s, and gas began to be generated on the surface of aluminum honeycomb sandwich plate at 50s, while foamed aluminum had no obvious change.

The lightweight structure, energy absorption and noise control of foamed aluminum make it widely used in automobile, railway and other transportation fields. German Karmann Co., Ltd. has selected foamed aluminum sandwich plate to manufacture passenger car top cover plate and bottom plate. Its stiffness is 7 times larger than the original steel components, and its mass is 25% lower than the original steel components. South Korean railway passenger cars have adopted foamed aluminum sandwich panels to make roof.

Foamed aluminum has strong absorption of collision energy, produces plastic deformation when impacted, absorbs the impact force of external load, and can effectively protect the safety of vehicles and personnel. When a car with a mass of 1500 kg collides at the speed of 48 km / h, the impact area is calculated as 1000 mm × Calculated as 150 mm and 20 mm thick, it can absorb 84% of the total impact energy. Therefore, the front end of railway passenger car drivers

Foamed aluminum is used to replace foamed plastic or FRP for components, which can improve service life and reduce maintenance. At the same time, it also eliminates the harmful gas produced by traditional materials, so as to greatly reduce the loss and casualties in traffic accidents. Railway passenger cars generally use glass wool as the main sound-absorbing material. With the extension of application time, the moisture content in glass wool will continue to increase, resulting in glass wool

The internal structure of cotton collapses, forming a macroporous environment, and the whispering performance decreases gradually. If foamed aluminum can be applied to the indoor silencing of railway passenger cars, it can be installed once and used permanently, and its sound absorption effect will not be reduced with the extension of time, and there is no potential fire hazard. In order to improve the fire prevention performance and noise reduction effect of high-speed train, foamed aluminum materials are used in almost all interior parts of the train, such as floor, side wall, partition wall and roof, in the carriage of Korean km2 high-speed train. Japan's Shinkansen sightseeing bus also selects foamed aluminum as the sound insulation wall to reduce the noise generated by generators, fans, air conditioners and other equipment. At present, foamed aluminum materials have been successfully used in Shanghai subway and Beijing Batong subway in China.

Foamed aluminum for railway passenger cars will have broad application prospects in the development of railway passenger cars in the future because of its excellent properties such as ultra light, sound absorption, flame resistance, energy absorption and environmental protection.

Free offer of products, welcome to consult at any time, we will give the first reply.Our Email: