86 17344894490

service@chalcoaluminum.com

- Aluminum Forgings for Rail Vehicles

- Aluminum plate sheet for rail Rail vehicles

- Aluminum Profile for Rail Vehicles

Application of Aluminum Extruded Profiles in the Rail Transportation Field

Aluminum is the most abundant metal element in the earth's crust. Aluminum products have become the second largest metal material after steel. They are widely used in aerospace, rail transit, automobile, ship, engineering structure, electronic machinery, petrochemical industry, infrastructure and other fields. With the national policy guidance and huge market demand, aluminum alloy extruded profiles have played an important role in the field of rail transit in recent ten years because of their light weight, corrosion resistance, high specific strength, easy processing and molding, moderate cost and other advantages, which has greatly promoted the development of the industry and facilitated people's travel.

Aluminum Extruded Profiles in the Rail Transportation Field

Advantages of aluminum profile for rail transit car body

As early as the middle of the 20th century, Europe, America, Japan and other countries have begun to explore the use of aluminum profile to manufacture railway vehicles to replace steel to reduce weight. At present, aluminum alloy materials have been widely used in most rail transit train bodies in the world. According to the goal of weight reduction and the requirements of aerodynamics, the high-speed train body with a speed of more than 300 kilometers per hour must use lightweight materials, and the train body with a speed of more than 350 kilometers must use lightweight materials except the chassis. The aluminum profile of rail transit came into being.

The development of aluminum profile car body in China began in the 1990s. At present, among the four types of CRH1, CRH2, CRH3 and CRH5 used in EMUs of passenger dedicated railway, except that CRH1 car body is made of stainless steel, the other three types of EMU car bodies are made of aluminum alloy. The materials used for manufacturing rail transit car bodies mainly include carbon steel, stainless steel, aluminum alloy and composite materials, of which aluminum alloy is the most important

And stainless steel. Table 1 shows the performance comparison of these four materials. It can be seen that the comprehensive performance advantages of aluminum alloy car body are obvious. Light weight reduction, energy saving and consumption reduction. The density of aluminum alloy is about 2.7g/cm3, which is about 1 / 3 of that of steel. At the same time, it has a good match of strength, plasticity and toughness. The application of aluminum profile in train body can not only meet the requirements of passenger safety and travel comfort, but also greatly reduce self weight, energy consumption and environmental pollution. According to statistics, the aluminum alloy used in a train carriage is about 9 tons, and if all steel is used, it can reach 12-13.5 tons; Moreover, for every 10% reduction in train weight, the fuel can be saved by 8%, and the effect of energy saving and consumption reduction is significant. Easy to process and shape, easy to maintain. Aluminum alloy has excellent processing and molding performance and module welding performance. With the improvement of process technology, some enterprises in China have the ability to extrude and produce large section, special-shaped, thin-walled and hollow profiles of more than 30 meters in a single time, and have good performance. The deep processing of aluminum profile only needs blanking, assembly and large robot assembly and welding. The later maintenance is simple, easy to replace, no rust removal is required, the process is simple and the workload is small [3].

Excellent corrosion resistance. The surface of aluminum alloy is easy to form a uniform and dense oxide film naturally, which has excellent corrosion resistance in atmospheric environment. Especially for some components with complex shape and difficult to paint, aluminum alloy has more obvious advantages. If anodizing, electrophoresis, spraying and other surface treatment technologies are used, the corrosion resistance of aluminum profile will be further improved, which is more beneficial to prolong the service life of train body.

Sound insulation and noise reduction, beautiful and generous. Aluminum profile can be anodized, colored and sealed, so that the profile has different colors, good decoration and looks solemn and generous; Moreover, the hollow structure of aluminum profile has good sealing performance, which is conducive to sound insulation, noise reduction and high comfort. The cost is moderate. Relatively speaking, the price of aluminum profile is high and the manufacturing cost increases. However, aluminum profile realizes the lightweight of train body, and brings the advantages of increased transport capacity, reduced energy consumption, simple maintenance and low cost. Moreover, the recycling value of aluminum alloy body when scrapped is about 4.8 times that of steel body. Therefore, from the perspective of life cycle, the cost of aluminum alloy car body is moderate and economical.

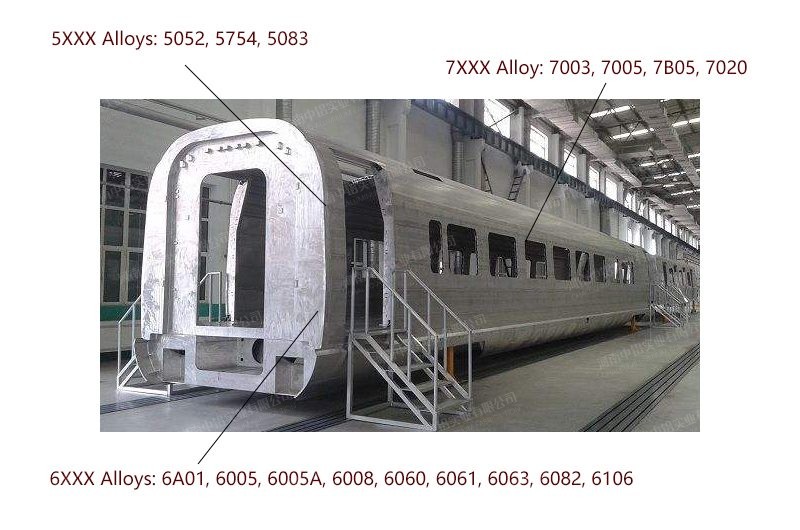

At present, the aluminum alloy used for manufacturing rail transit car body in China mainly includes 5xxx series, 6xxx series and 7xxx series, of which 5xxx series has three grades of 5052, 5754 and 5083, 6xxx series has nine grades of 6a01, 6005, 6005A, 6008, 6060, 6061, 6063, 6082 and 6106, and 7xxx series has four grades of 7003, 7005, 7b05 and 7020, which are mainly used for the production of side wall, ceiling, floor Underframe, traction beam, cross beam, sleeper beam, skirt, end wall, energy absorbing parts, equipment cabin, car body interior decoration and other rail transit car body profiles, and most of them are large, thin-walled, hollow and special-shaped profiles. With the development of car body material application,

In China, 6a01 and 7b05 alloys are mainly used for high-speed railway body materials, while 6005A and 6082 alloys are mainly used for urban rail transit body materials. It is estimated that the total demand for aluminum materials of domestic passenger rail vehicles during the 13th Five Year Plan period is about 253000 tons, of which the total demand for aluminum materials of high-speed railway vehicles is 132000-156000 tons, the demand for intercity railway is 10000 tons, and the demand for urban rail (including maglev, medium and low speed maglev, subway, elevated urban rail, urban fast rail, urban monorail, etc.) is 72000 tons. In addition, some aluminum materials are also required for the construction of in car facilities such as luggage rack, storage cabinet, sanitary facilities, air conditioning and ventilation system, lighting and communication system, station and other facilities.

Free offer of products, welcome to consult at any time, we will give the first reply.Our Email: