86 17344894490

service@chalcoaluminum.com

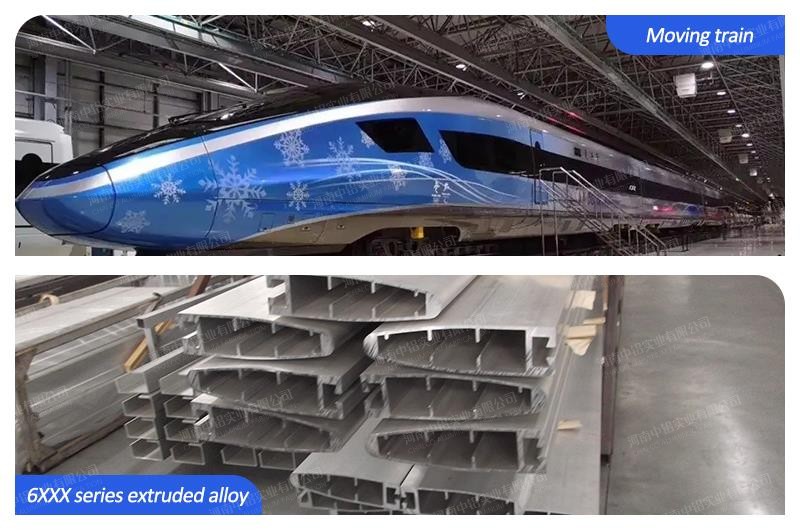

- Aluminum Forgings for Rail Vehicles

- Aluminum plate sheet for rail Rail vehicles

- Aluminum Profile for Rail Vehicles

6005A Aluminum Alloy Profiles for High Speed Rail EMU

Aluminum is a relatively young metal. Its entire development history is no more than 200 years, and the industrial production scale only began at the beginning of the 20th century. In the engineering field, aluminum has always been regarded as "opportunity metal" or "hope metal", and the aluminum industry has always been regarded as "sunrise industry", with a very fast development speed. Aluminum has been widely used, it has become an important basic material for developing the national economy and improving people's material and cultural life in the industries of transportation, packaging containers, aerospace, energy and power. Especially in the aspect of rail transit, aluminum alloy profiles have been used to replace the traditional steel in the subway and light rail. In terms of railway transportation, the running speed of China's railway trains is very slow. Before the emergence of EMUs, almost all of them were below 200 km / h. In order to improve the running speed of trains, it is necessary to reduce the dead weight of the car body. It has become an irreversible trend to replace steel with aluminum. The car body structure of EMUs represented by the sixth large speed increase of China's railway is made of aluminum alloy extruded profiles.

At present, 6xxx series extrusion alloys for industrial use are characterized by good extrudability, weldability and low cost for obtaining appropriate strength. Therefore, 6xxx alloy is regarded as the main material in the application of lightweight structures all over the world. Among 6xxx series alloys, 6005A aluminum alloy is an Al Mg Si series heat-treatment hardenable wrought aluminum alloy developed in Europe. It not only has high tensile strength and non proportional stress, but also has good elongation after fracture. In order to obtain both good service performance and good process performance of the alloy, after a lot of experimental research and comparative analysis, it is decided to select 6005A aluminum alloy profiles for high speed rail EMU. However, the alloy has strong quenching sensitivity and poor extrusion performance. Therefore, the alloy composition is optimized on the basis of 6005A, a small amount of transition group elements are added to improve the corrosion performance of the alloy material, and a small amount of rare earth elements are added to refine the grain of the aluminum rod to a level close to the nanometer level, resulting in comprehensive properties such as high mechanical properties, corrosion resistance and weldability. Heat treatable and strengthened Al Mg Si alloy is a good combination of strength, toughness, corrosion resistance, weldability and extrusion process performance. The tensile strength of this alloy in T6 state (peak aging) is in a wide range of 200 -360mpa.

6005A aluminum alloy is selected as the basic alloy for the car profile of high-speed EMU, the alloy composition is optimized according to the comprehensive performance of the product, the reasonable melting, casting, extrusion and heat treatment processes are adopted, and the production process is strictly controlled. Finally, alloy profiles for high speed rail EMU meeting the requirements of users are prepared.

Free offer of products, welcome to consult at any time, we will give the first reply.Our Email: